Reselling semiconductor lithography systems and refurbishing their lenses

For almost two decades, Nikon has promoted the reuse of semiconductor lithography equipment to reduce waste.

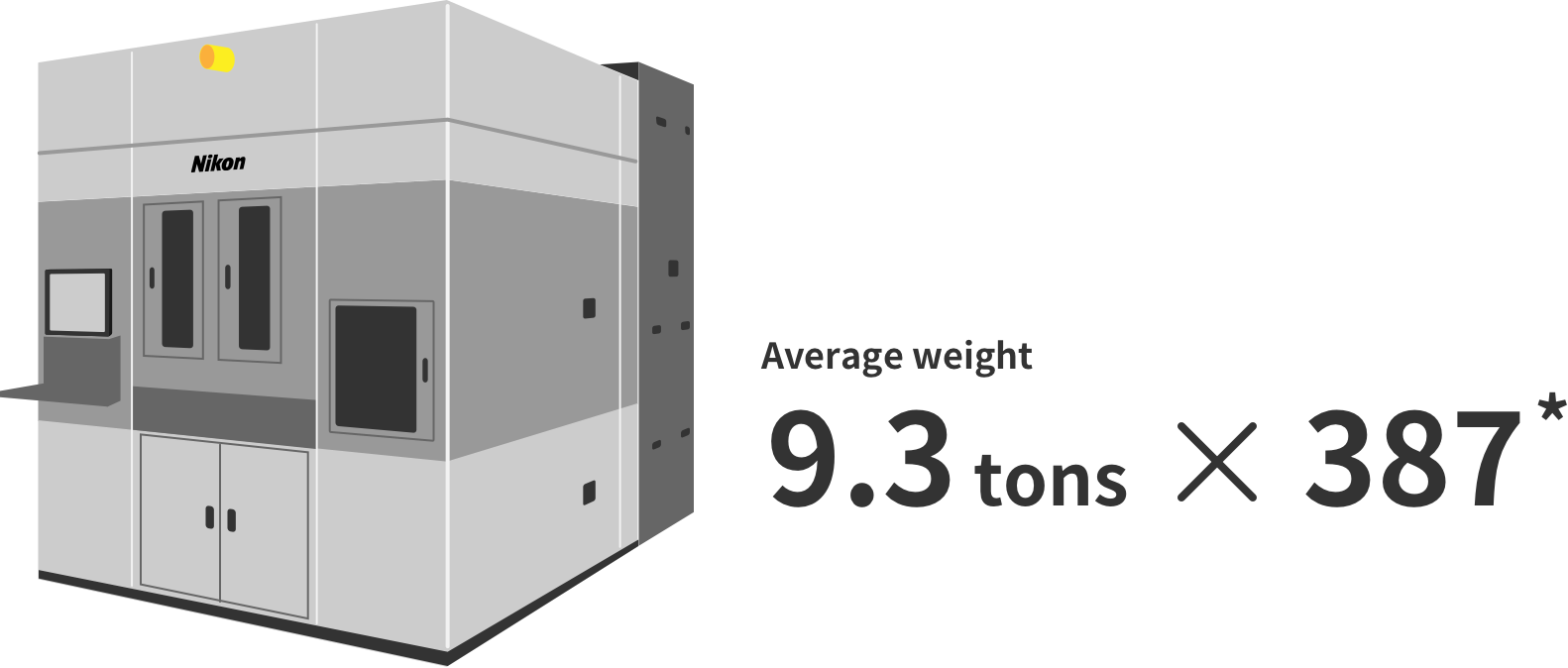

Nikon manufactures the semiconductor lithography systems essential to semiconductor production. After customers finish using these systems, Nikon buys them back, restores their parts and components, and resells them. Nikon launched this business initiative to reuse the systems in 2000—ahead of its competitors in the industry. By March 2018, 371 systems had been resold, effectively reducing the materials that would have been disposed of by about 3,600 tons. Lithography systems have grown larger in size with advancements in semiconductor products, so their reuse has become increasingly important for reducing waste matter.

* 371 semiconductor lithography systems and 16 refurbishing lenses

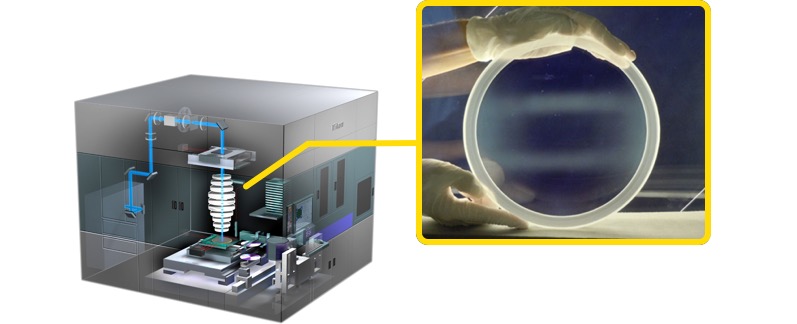

Nikon has also promoted reuse and reduce initiatives for the projection lenses fitted in these lithography systems. While these systems have an operational life of more than 20 years, the projection lenses gradually deteriorate due to ultraviolet rays and other light sources. When they reach the end of their service life, Nikon refurbishes the lenses. By using these replacement lenses that meet latest specifications, Nikon enables the lithography equipment to be used for a longer period, reducing waste and realizing higher quality products.